I plan to run both 93-octane pump gas and E85. E85 is a blend of 85% ethanol and 15% gasoline by volume. If you’re wondering why I want to run my car on corn juice and what it takes to do so, read on.

Corn is Cool

When fuel vaporizes in an intake system, it has a cooling effect referred to as the latent heat of vaporization which is expressed in BTUs per pound; ethanol is 396 and gasoline is approximately 150. So what does this 2.6x increase in cooling equate to?

Apparently motors will typically run 15-20 degrees cooler on E85 than gasoline. Given that one of the largest challenges with a mid-engine car is heat management in the engine compartment, this is a very desirable benefit for a SL-C.

In addition, a cooler combustion charge has two significant performance benefits. First, a cooler combustion charge is more dense which improves volumetric efficiency, which improves cylinder pressure which improves power:-) The performance gains are significant on high-boost supercharged or turbocharged engines which heat the intake air as a negative side effect of compressing it. This is exactly why intercoolers are used.

Secondly, when E85’s cooler combustion charge is coupled with its higher octane rating (typically 105 or above), it becomes very resistant to detonation which means you can run more boost, more compression, more ignition advance, or all three.

Fuel Consumption

In a previous post I discussed my fuel pump requirements assuming a Brake-Specific Fuel Consumption (BSFC) of 0.65 at wide-open throttle. However, ethanol only contains 82,000 BTU per gallon whereas gasoline contains approximately 115,000 BTU per gallon which means that ethanol has a higher BSFC. Since ethanol contains 40% less BTUs per gallon you need 40% more fuel to obtain the same power level! The following are rule-of-thumb BSFCs for different fuels in a forced-induction application:

Gasoline: 0.60 to 0.65

E85: 0.84 to 0.91

Methanol: 1.80 to 2.00

So my engine running on E85 at wide open throttle (i.e., 1,000 HP) requires 152 GPH. My high-pressure pump will handle that volume, but I’m now considering a low-pressure pump upgrade. I’ll also need to determine if I need to upgrade the fuel injectors.

Ethanol Blend

Ethanol requires more heat to vaporize than gasoline, which can cause cold start problems when the temperature drops below 20 degrees F. To solve this problem, the Federal Government allows up to a 30% gasoline content in E85, which essentially makes it E70. Apparently cranking in cold climates is the primary reason ethanol is blended with any gasoline (i.e., in Brazil pure ethanol is used).

Most pump gas is blended with 10% ethanol (E10) so depending on what was in the tank when I filled up, what I filled up with and the time of year, I’ll be running om something between E10 and E85.

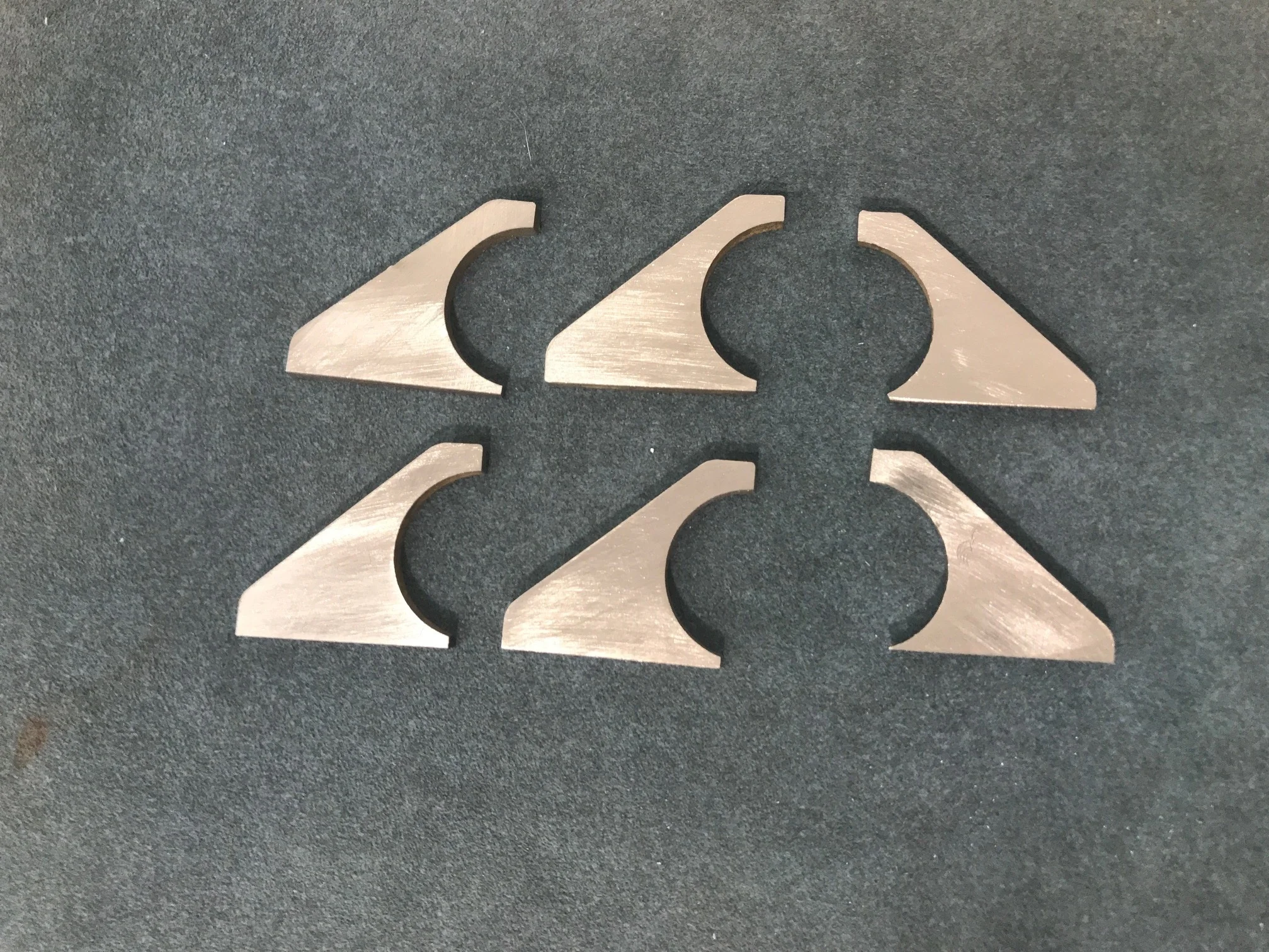

Ethanol Content Sensor

Small changes in the amount of ethanol content will cause air/fuel ratio changes that have a significant effect on vehicle driveability. As the amount of ethanol in the fuel is decreased, the mixture becomes richer. To enable the ECU to change the tune on-the-fly based on the amount of ethanol I installed a ethanol content sensor (Continental 13577379) which is apparently widely used by OEMs and tuners. The inlet and outlet are straight aluminum tubes with a raised ridge and I wasn’t sure how to connect an AN fitting to it. Fortunately, Fore Innovations (and I assume others) offers multiple AN Male to EFI Female Adapters.